Introduction: In the fast-paced world of modern industry, precision and efficiency are paramount. Every degree of inclination, every millimeter of movement, and every accurate measurement can mean the difference between success and failure. This is where digital inclinometers step into the spotlight. These remarkable devices play a pivotal role in enhancing precision, safety, and efficiency across various industries. In this blog, we’ll explore the vital role of digital inclinometers in today’s industrial landscape.

Precision at its Finest :

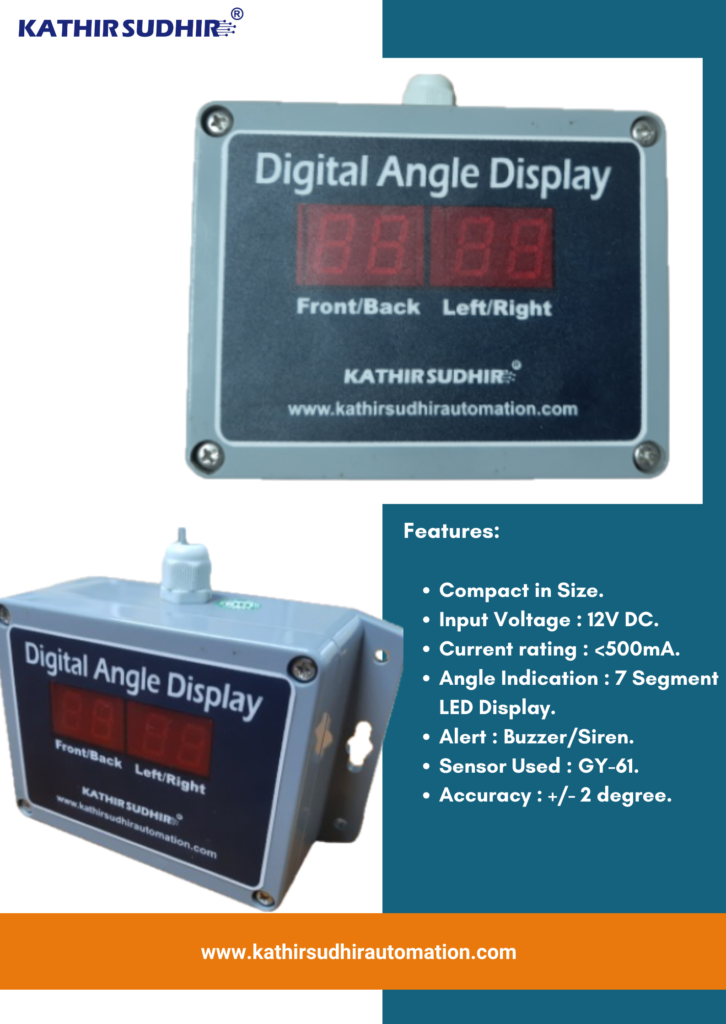

Precision is the bedrock of industry, and digital inclinometers are the unsung heroes that make it possible. These advanced tools provide real-time, highly accurate measurements of angles and inclinations, ensuring that critical components and machinery are aligned with precision. This is especially crucial in applications like manufacturing, where even the slightest deviation from the desired angle can lead to costly errors, rework, or safety hazards.

Digital inclinometers are capable of measuring angles down to fractions of a degree, allowing industrial professionals to fine-tune their machinery and processes with remarkable accuracy. Whether it’s aligning heavy machinery, ensuring that structures are level, or calibrating sensors, digital inclinometers provide the data needed to achieve exceptional precision.

Safety First :

Safety is a non-negotiable priority in industrial settings. The incorrect alignment of equipment or structures can lead to dangerous situations, accidents, and even disasters. Digital inclinometers contribute significantly to enhancing safety in industries by helping professionals maintain and monitor critical parameters.

For example, in construction and civil engineering, the proper alignment of structures is essential to ensure stability and safety. Digital inclinometers provide real-time data to construction workers and engineers, allowing them to detect even minor deviations and take corrective action promptly. This minimizes the risk of structural failures, which can have catastrophic consequences.

In the automotive industry, during vehicle assembly, digital inclinometers help ensure that components are installed at the correct angles, reducing the chances of vehicle malfunctions that could endanger drivers and passengers. These inclinometers are also employed in crane and material handling operations to prevent dangerous load imbalances and tip-overs.

Enhanced Efficiency :

Efficiency is the lifeblood of any successful industry. Digital inclinometers play a pivotal role in optimizing processes and workflows by ensuring that equipment operates at its peak performance. For instance, in the field of agriculture, the use of digital inclinometers on tractors and farming equipment helps ensure that fields are tilled, planted, and harvested with maximum efficiency. This technology also minimizes soil erosion and optimizes the distribution of water resources.

In the aerospace industry, during aircraft maintenance, digital inclinometers assist in ensuring that aircraft components are perfectly aligned, thereby contributing to fuel efficiency and reducing maintenance costs. This not only saves money but also minimizes the environmental impact of aviation.

Conclusion

Digital inclinometers are the unsung heroes of the industrial world, contributing to precision, safety, and efficiency in a multitude of applications. They empower professionals to align machinery, structures, and processes with remarkable accuracy, reducing the risk of accidents, and improving overall productivity. Whether it’s manufacturing, construction, agriculture, or aerospace, the role of digital inclinometers is undeniable.

As industries continue to evolve and demand ever-increasing levels of precision and safety, digital inclinometers will remain essential tools for meeting these demands. Embracing these technological advancements is not just a choice but a necessity for those who seek to thrive in the fast-paced, competitive landscape of modern industry.