Introduction: In the ever-evolving world of manufacturing, precision, speed, and efficiency are paramount. To meet these demands, manufacturers rely on a wide range of machines and equipment, each designed for specific tasks. Special Purpose Machines (SPMs) have emerged as a game-changer in this context, streamlining complex and specialized operations. However, the efficiency and productivity of SPMs depend significantly on the brain behind the brawn: the Special Purpose Machine Controller. In this blog, we delve into the world of SPM controllers, exploring their functions, benefits, and the role they play in modern manufacturing.

The Heart of SPMs

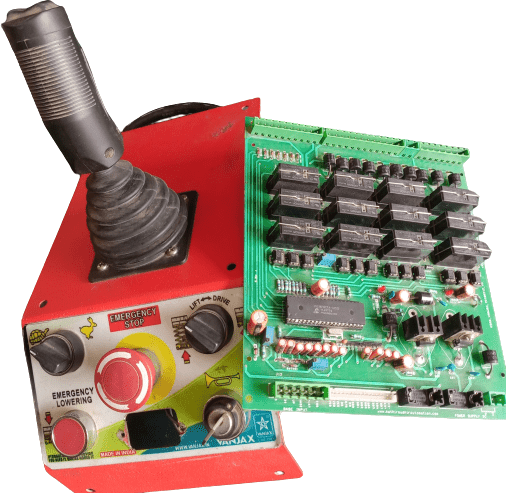

Special Purpose Machine Controllers are the central nervous system of specialized manufacturing equipment. They are responsible for orchestrating the intricate dance of movements, processes, and actions that these machines perform. SPM controllers are designed to handle the unique requirements of each SPM, ensuring precise and repeatable performance.

- Customization: SPM controllers are highly adaptable and can be customized to suit the specific needs of the machine they control. Whether it’s a laser cutting machine, a robotic assembly line, or a packaging system, the controller can be tailored to optimize performance.

- Real-time Control: Manufacturing processes often require split-second decisions and precise adjustments. SPM controllers operate in real-time, allowing them to respond swiftly to changing conditions and maintain the desired level of accuracy.

- Integration: In today’s interconnected manufacturing environments, SPM controllers play a vital role in integrating multiple machines and processes. They facilitate communication between different components, ensuring seamless operation and data exchange.

- Safety: Safety is a top priority in manufacturing. SPM controllers are equipped with safety features that can instantly halt operations in case of emergencies, protecting both equipment and personnel.

- Data Monitoring and Analysis: SPM controllers are not just about control; they are also data hubs. They collect data from sensors and other devices, enabling manufacturers to monitor performance, identify bottlenecks, and make informed decisions for process improvement.

Benefits of SPM Controllers

Now that we understand their functionality, let’s explore the benefits of integrating Special Purpose Machine Controllers into your manufacturing setup:

- Enhanced Productivity: SPM controllers can significantly boost production rates by minimizing downtime, reducing errors, and optimizing workflows.

- Improved Precision: Achieving the highest level of precision is essential in industries such as aerospace, medical device manufacturing, and microelectronics. SPM controllers excel at delivering consistent, micron-level accuracy.

- Cost Savings: By maximizing efficiency and minimizing waste, SPM controllers can lead to substantial cost savings over time.

- Scalability: As your manufacturing needs evolve, SPM controllers can adapt and grow with you. This scalability ensures that your investment remains relevant and valuable.

- Quality Assurance: The ability to monitor and control processes in real-time ensures that every product meets the highest quality standards.

- Reduced Labor Dependency: Automation driven by SPM controllers can reduce reliance on manual labor, which is particularly beneficial in industries facing labor shortages.

Challenges and Considerations

While Special Purpose Machine Controllers offer numerous advantages, there are some challenges to be aware of:

- Initial Investment: Customizing and integrating SPM controllers can be costly upfront, but the long-term benefits often outweigh the initial investment.

- Skill Requirements: Operating and maintaining SPM controllers may require specialized training and expertise.

- Maintenance: Regular maintenance is essential to ensure the continued smooth operation of SPM controllers and the machines they control.

Conclusion

In the world of manufacturing, where precision and efficiency reign supreme, Special Purpose Machine Controllers have emerged as indispensable tools. Their ability to tailor operations, optimize processes, and drive automation makes them a cornerstone of modern manufacturing. By investing in SPM controllers, manufacturers can not only stay competitive but also lead the charge toward a more efficient and productive future.