A chilly morning at an automotive testing lab in Pune. The floor hums with machines. Engineers walk between test rigs, checking load cycles and test parameters. Among them, Ravi — a test rig technician — watches an actuator gently press down on a brake pedal, again and again, for the 10,000th time that week.

But this isn’t just any testing system. It’s powered by an electric linear actuator — quiet, clean, and shockingly precise.

From Leaky Pipes to Precision Engineering

Just a year ago, Ravi’s team was dealing with a bulky pneumatic system. It leaked, was noisy, and demanded constant maintenance. Every pressure drop stalled testing. Setting force and speed meant fiddling with valves and hoping for consistency.

“When the boss said we’re switching to electric actuators, we thought: Really? For testing brakes?” Ravi recalls with a smile.

But the results changed everything.

The Shift to Electric

Within weeks, the new actuator-based system was installed. It was compact, fully programmable, and didn’t need an air compressor or hydraulic tank.

Engineers could now:

- Set precise force and stroke from a laptop

- Repeat thousands of cycles with zero deviation

- Save test profiles for different models

More importantly, no oil leaks, no hiss of compressed air, no downtime.

Real Applications, Real Impact

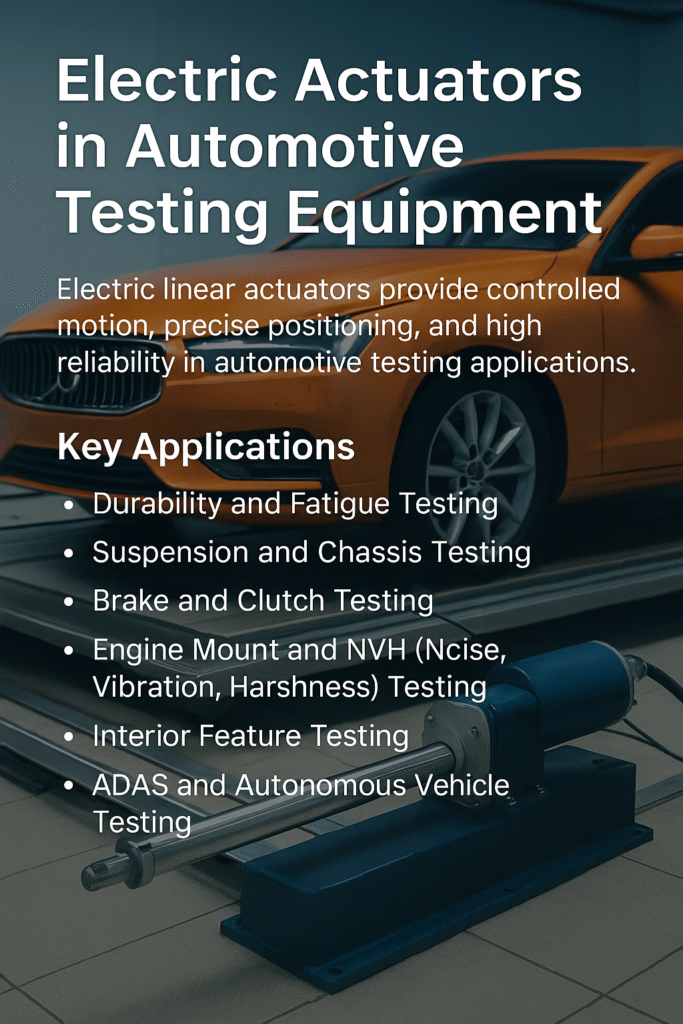

The lab didn’t stop there. Electric actuators slowly replaced manual and pneumatic setups in:

- Suspension testing rigs, simulating bumpy roads

- Door closing tests, checking latch durability

- Pedal force tests, validating ergonomics

- EV battery mount testing, ensuring shock resistance

Each system became smarter, cleaner, and easier to operate.

A Future Built on Precision

Automotive testing is not just about validation — it’s about confidence before production. With electric actuators, Ravi’s team could now simulate real-world conditions down to the millimeter.

Whether it’s simulating a 60kg driver pressing the brake, or testing a trunk latch for 50,000 opens and closes — it’s all automated, safe, and accurate.

And in EVs and autonomous vehicle testing? Electric actuators are now indispensable.

Why This Story Matters

This story isn’t just about one lab in Pune. Across India, automotive OEMs and test labs are realising that electric actuators offer unmatched precision, reliability, and ease of integration.

They don’t just replace pneumatic systems. They redefine how motion is applied in critical testing.

From being seen as “only for automation lines,” electric actuators are now becoming the unsung heroes of quality and durability testing.

Final Words from Ravi

“These actuators? They don’t complain. They don’t leak. They just keep doing the job exactly how we want.”

That’s the promise of electric actuators in automotive testing. And that’s the future of reliable, data-driven engineering in India.