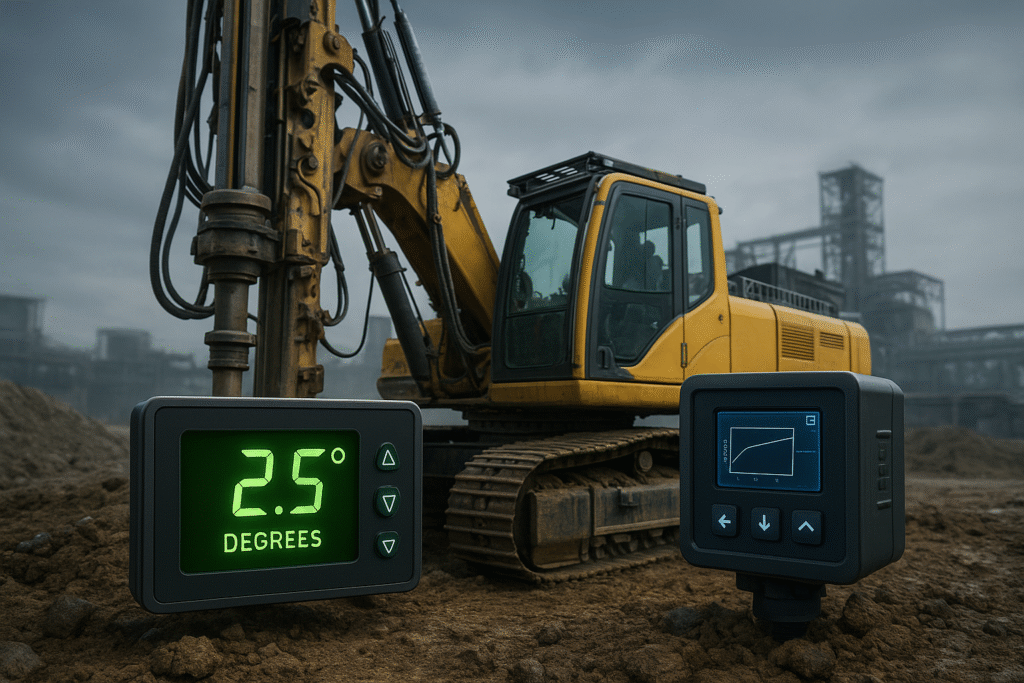

In heavy-duty drilling and rig operations, precision is everything. Uneven positioning of rig machines not only reduces efficiency but also increases risks of equipment wear, instability, and safety hazards. To overcome these challenges, Digital Angle Indicator/Display with Integrated Controller systems are becoming the go-to solution for accurate machine leveling.

The Challenge of Levelling in Rig Machines

Rig machines operate in tough and uneven terrains, making manual leveling a time-consuming and error-prone process. Traditional bubble levels or mechanical indicators provide only approximate accuracy and require constant operator monitoring. For modern rig operations, where reliability and efficiency matter, a more advanced solution is essential.

The Role of a Digital Angle Indicator/Display

A Digital Angle Indicator/Display provides real-time feedback of machine tilt or angular position with high accuracy. By continuously monitoring the machine’s angle, operators can instantly identify deviations and take corrective measures. Key benefits include:

- High Precision: Accurate angle measurement in degrees for precise machine alignment.

- Easy Readability: Bright digital display makes monitoring simple even in outdoor conditions.

- Instant Feedback: Operators can quickly adjust and maintain proper leveling.

Integrated Controller System – The Next Level of Automation

Pairing the digital angle indicator with an integrated controller system transforms it from a monitoring device into a complete automation solution. The controller automatically adjusts actuators or hydraulic systems to correct tilt and maintain balance without manual intervention.

How It Works:

- The sensor detects machine tilt and sends data to the digital indicator.

- The integrated controller processes the angle deviation.

- Corrective signals are sent to electric or hydraulic actuators.

- The rig machine is automatically leveled in real-time.

Advantages of Using Digital Angle Display with Controller in Rig Machines

- Automated Levelling: Reduces human error and operator fatigue.

- Improved Safety: Prevents accidents due to machine imbalance.

- Higher Productivity: Saves time during rig setup, allowing faster drilling operations.

- Durability: Designed to withstand vibration, dust, and harsh rig environments.

- Flexibility: Can be integrated with both electric linear actuators and hydraulic systems.

Applications in Rig Industry

- Drilling Rig Machines – maintaining vertical alignment for accurate drilling.

- Pile Driving Machines – ensuring correct hammer alignment for stability.

- Offshore Rigs – balancing in fluctuating terrains and water conditions.

- Heavy Construction Equipment – ensuring structural accuracy and safety.

Conclusion

The Digital Angle Indicator/Display with Integrated Controller system is revolutionizing how rig machines achieve and maintain proper leveling. By combining precision measurement with automatic correction, it enhances safety, efficiency, and reliability in tough field conditions. For companies seeking to improve drilling accuracy and operator safety, adopting this advanced leveling solution is no longer optional – it’s a necessity for the future of rig automation.