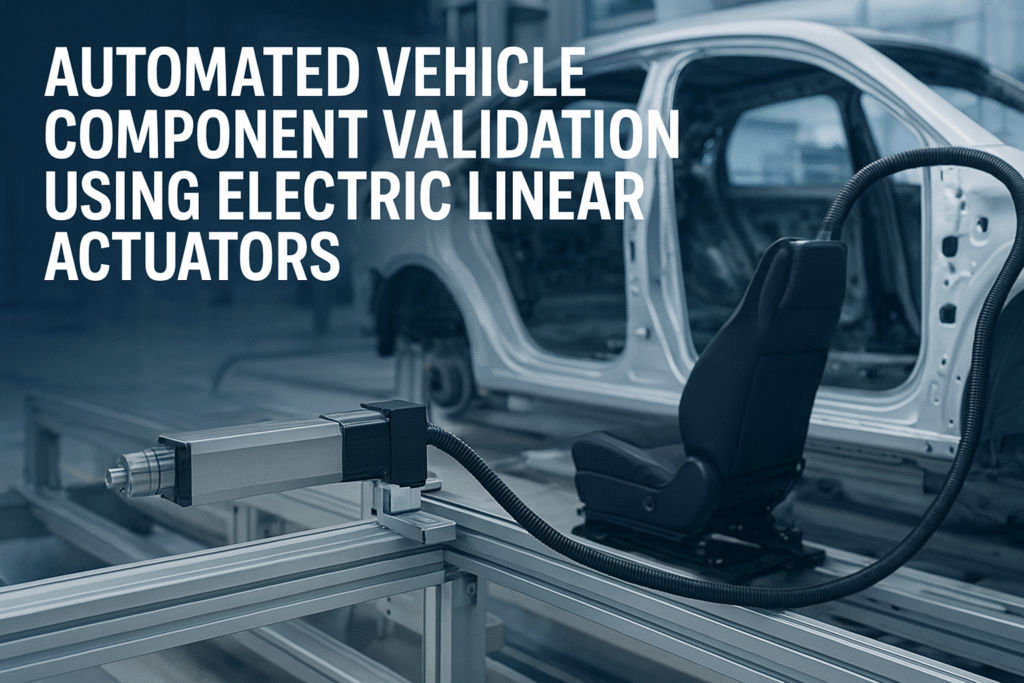

The automotive industry is evolving at an unprecedented pace, driven by innovations in safety, comfort, performance, and sustainability. With this rapid advancement comes the crucial need for rigorous component validation to ensure vehicles meet global standards for reliability and durability. One technology enabling this transformation is the electric linear actuator, which plays a vital role in automated vehicle component testing and validation.

Why Component Validation Matters in Automotive Industry

Before vehicles hit the road, every component—from seats and doors to engine parts and infotainment systems—must undergo strict validation tests. This ensures they can withstand real-world conditions such as vibration, temperature fluctuations, repetitive motion, and wear and tear. Manual testing is time-consuming and prone to inconsistencies, making automation the preferred choice for modern manufacturers.

Role of Electric Linear Actuators in Validation

Electric linear actuators are increasingly being integrated into automated testing systems. Their ability to deliver precise, repeatable, and programmable linear motion makes them an ideal solution for component validation. Unlike pneumatic or hydraulic actuators, electric actuators offer cleaner operation, higher energy efficiency, and finer control over force and speed.

Key Applications in Vehicle Component Validation

- Seat Durability Testing

Electric actuators simulate thousands of cycles of reclining, sliding, and height adjustments to evaluate the durability of automotive seats. This ensures comfort and performance over years of usage. - Door and Window Mechanism Testing

Actuators can repeatedly open and close doors, windows, and tailgates, mimicking real-world usage to validate strength, safety, and reliability. - Switch and Button Testing

Control buttons, infotainment knobs, and switches undergo repeated actuation by linear actuators to confirm longevity and response quality. - Dashboard and Console Testing

Electric actuators simulate user interactions with infotainment panels, ensuring components can handle frequent inputs without failure. - Engine and Transmission Components

They can replicate motion loads, vibration patterns, and stress levels to validate performance under varying operational conditions.

Benefits of Using Electric Linear Actuators in Validation

- High Precision: Ensures repeatability in test cycles.

- Programmability: Motion profiles can be customized for different components.

- Energy Efficiency: Consumes less energy compared to pneumatic/hydraulic systems.

- Clean Operation: No oil leaks, making them suitable for sensitive testing environments.

- Data Integration: Works seamlessly with sensors and software for real-time data logging.

Driving Efficiency in Automotive R&D

By using electric actuators, automotive companies can significantly reduce validation timelines while ensuring more reliable results. This leads to faster product development cycles, better quality assurance, and improved customer satisfaction.

Conclusion

Electric linear actuators are redefining how the automotive industry approaches component validation and durability testing. With their precision, efficiency, and adaptability, they have become an essential tool for manufacturers striving to meet evolving market demands and regulatory standards.

As the automotive sector continues to innovate, automation powered by electric actuators will remain central to ensuring safe, durable, and high-quality vehicles for the future.