HVAC systems play a major role in modern buildings. They do more than just heat or cool air. In fact, they directly affect energy use, comfort, air quality, and equipment life. Because of this, airflow controller has become essential. Without airflow monitoring, HVAC systems work blindly. Although the system may be running, it does not know if the right amount of air is being delivered. As a result, energy is wasted, comfort drops, and equipment damage becomes more likely. Therefore, an Airflow Monitoring & Control System is critical for reliable and efficient HVAC operation.

Why Airflow Monitoring Is Essential in HVAC Systems

1. Improves Energy Efficiency and Reduces Costs

First of all, airflow has a direct impact on energy consumption. If airflow is too high, the system overworks. This leads to unnecessary heating, cooling, or ventilation. On the other hand, if airflow is too low, the system runs longer to compensate. Because airflow monitors measure air volume accurately, HVAC units can operate at optimal levels. As a result, energy waste is reduced, and operating costs go down. Moreover, optimized airflow helps facilities meet energy-efficiency targets and sustainability goals.

2. Ensures Better Occupant Comfort

In many buildings, uneven airflow creates hot and cold spots. Consequently, occupants feel uncomfortable. This is common in offices, hospitals, hotels, and commercial spaces. By continuously monitoring airflow, the system ensures even air distribution. Therefore, temperature and humidity remain stable. In addition, occupants experience consistent comfort throughout the space. As a result, productivity and satisfaction improve.

3. Maintains Indoor Air Quality (IAQ)

Airflow monitoring is also critical for indoor air quality. HVAC systems must supply the correct amount of fresh outdoor air. Otherwise, pollutants can build up. By measuring airflow, the system confirms proper ventilation. Furthermore, it prevents problems such as mold growth, stale air, and static electricity. In short, airflow control protects both health and compliance.

4. Protects HVAC Equipment and Extends Lifespan

Changes in airflow often signal hidden problems. For example, clogged filters, blocked ducts, or fan failures all reduce airflow. However, an airflow monitoring system detects these changes early. Because of this, maintenance teams receive alerts through sound alarms, SMS, or email. As a result, issues are fixed before they cause serious damage. This reduces downtime and prevents costly repairs.

5. Confirms Actual System Performance

Many HVAC systems are assumed to work correctly just because they are turned on. However, this is not always true. Airflow monitoring verifies that the system is delivering the designed airflow, not just running. Therefore, engineers can confirm that the system performs as intended. This is especially important during commissioning, audits, and performance validation.

Understanding Airflow Monitoring and Flow Measurement in HVAC

What Is an Airflow Monitor or Flow Meter?

An airflow monitor, also called a flow meter, measures air movement inside ducts. It calculates airflow using velocity or pressure data.

Depending on the application, the system may use:

- Thermal sensors

- Vane sensors

- Differential pressure sensors

Because these sensors provide real-time data, HVAC systems can respond immediately to airflow changes.

How Airflow Monitors Support HVAC Control Systems

How the Airflow Monitoring & Control System Works

An airflow monitoring system works as a closed-loop control system.

First, sensors measure airflow, temperature, and humidity. Next, the control unit compares actual values with set limits.

Then, fans and dampers are adjusted automatically. Finally, if airflow goes outside safe limits, the system sends alerts. Because of this process, airflow remains stable at all times. In addition, the system logs data for analysis and maintenance planning.

Choosing the Right Airflow Monitoring Solution for HVAC Applications

Airflow Monitors Designed for HVAC Environments

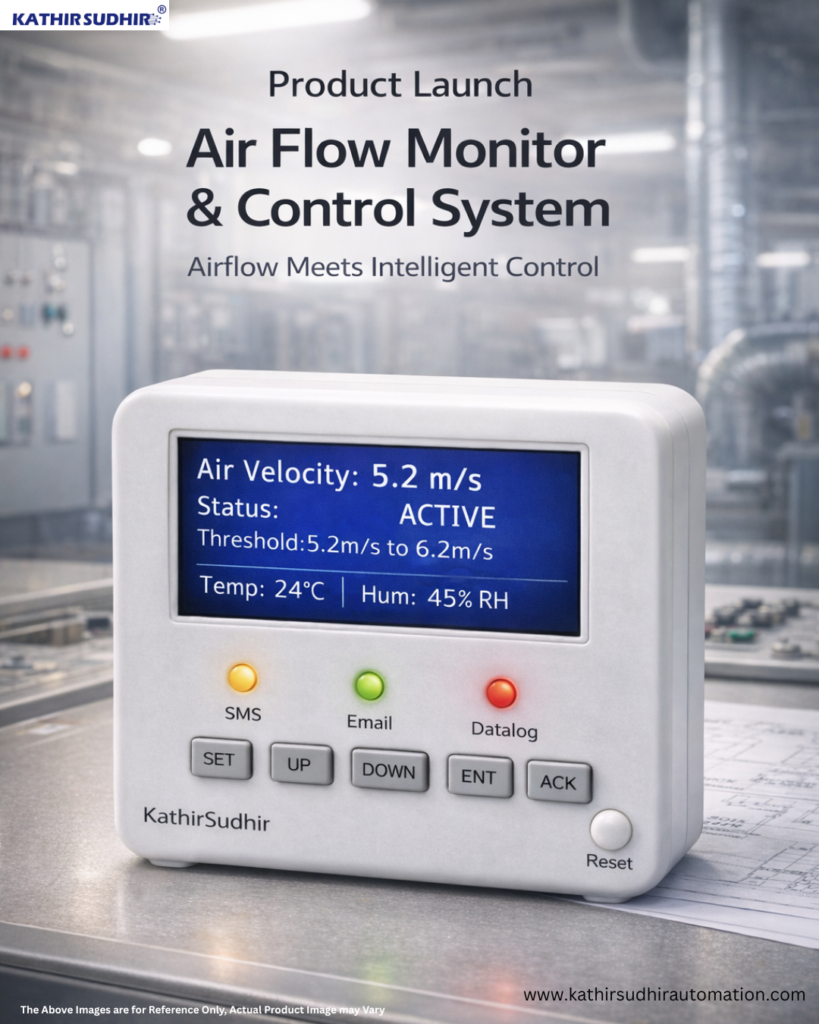

The Airflow Monitor & Control System is built for accuracy, flexibility, and reliability. Therefore, it fits many HVAC and ventilation applications.

Key Features

- High-precision airflow sensing

- Display of airflow (CFM), temperature, and humidity

- Threshold status indication

- Sound alarm, SMS alert, and email alert options

- Data logging for monitoring and reporting

- Easy customization

- RS485 / Modbus communication support

- Relay output for damper and actuator control

Because of these features, the system integrates easily into building automation systems.

Technical Specifications

- Operating Voltage: 12V / 24V / 230V AC

- Operating Temperature: –20°C to 60°C

- Measurement Range: 0–50 m/s (configurable by duct size)

- Accuracy: ±2–3% of reading

- Output Signals: 4–20 mA, 0–10 V, or Digital

- Relay Output for HVAC and damper control

Typical Applications

- HVAC systems

- Fume hood ventilation

- Industrial exhaust systems

- Laboratories and clean rooms

- Air filtration units

- Data centers

- Building automation systems

Conclusion: Smart HVAC Systems Start With Airflow Control

In conclusion, airflow Controller is not optional. It is a core requirement for modern HVAC systems.

Without airflow control, systems waste energy, reduce comfort, and risk equipment damage. However, with airflow Controller, HVAC systems become efficient, intelligent, and reliable.

Therefore, investing in an Airflow Controller ensures better performance, lower costs, and healthier indoor environments.