The fabrication industry has always been the backbone of manufacturing. From heavy machinery to automotive components, and from construction materials to precision tools, fabrication ensures raw materials like sheet metal, steel, and aluminum are transformed into usable products. Traditionally, this process relied heavily on manual labor and hydraulic or pneumatic systems. However, with the demand for accuracy, consistency, and efficiency, the industry is shifting toward electric actuators as a smarter and more sustainable solution.

Why Automation Matters in Fabrication

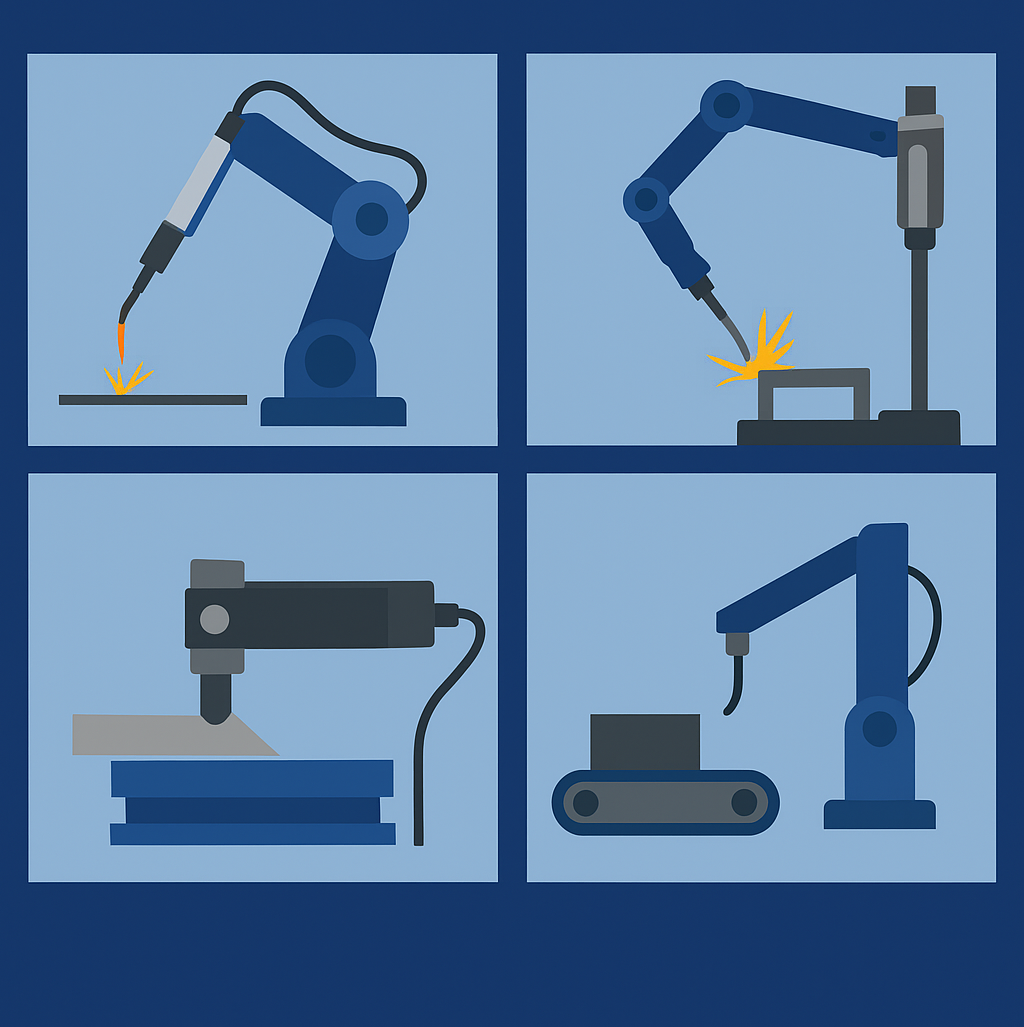

Fabrication involves multiple stages such as cutting, bending, welding, assembling, and finishing. Each step demands high precision and repeatability. Manual operations often lead to errors, inconsistency, and higher downtime. On the other hand, automation powered by actuators ensures smooth operation, consistent output, and improved worker safety.

Electric actuators, in particular, are becoming the preferred choice because they are cleaner, energy-efficient, and require less maintenance compared to hydraulic or pneumatic systems.

Key Applications of Actuators in Fabrication

1. Cutting Machines

Accurate cutting is one of the most critical steps in fabrication. Electric actuators are used to position and move cutting tools like plasma cutters, waterjet machines, and laser heads. By automating this movement, fabricators can achieve:

- Consistent cutting quality

- Reduced material wastage

- Faster cycle times

For example, in sheet metal fabrication, actuators guide the cutting table with millimeter-level precision, ensuring the same result every time.

2. Welding Automation

Welding is a common process in fabrication workshops, but it requires steady hands and proper positioning. Actuators make welding automation possible by:

- Holding workpieces in position

- Rotating and tilting materials for better access

- Moving welding heads with accuracy

This not only improves weld quality but also reduces operator fatigue and minimizes errors. Robotic welding stations equipped with electric actuators are now widely adopted in automotive fabrication.

3. Clamping and Pressing

Fabrication often requires pressing, bending, or holding materials in place. Traditionally, hydraulic clamps were used, but they involve oil leaks and high maintenance. Electric linear actuators provide the same strong clamping force with:

- Cleaner operation (no oil leakage)

- Adjustable force control

- Quiet and energy-efficient performance

This makes them ideal for bending machines, forming presses, and assembly fixtures.

4. Material Handling

Handling heavy materials safely is a big challenge in fabrication. Actuators are used in:

- Lifting arms for sheet loading

- Adjustable conveyors

- Tilting platforms for moving heavy parts

Automating these movements reduces worker injuries, increases productivity, and ensures smoother workflow inside workshops.

5. Painting and Finishing

The last stage of fabrication involves painting, polishing, or coating. Actuators help by:

- Adjusting spray guns and nozzles

- Moving panels during coating

- Controlling polishing machines

This ensures a uniform finish and reduces wastage of paint or chemicals.

Benefits of Electric Actuators in Fabrication

- High Precision – Essential for cutting, bending, and welding tasks.

- Energy Efficiency – Consumes power only when in use, unlike hydraulic systems.

- Low Maintenance – No need for oil, compressors, or complex piping.

- Environment Friendly – Cleaner and safer compared to hydraulic oil leakage.

- Flexibility – Easy to integrate with CNC machines, robotic arms, and automated lines.

Future of Actuators in Fabrication

With the rise of Industry 4.0 and smart factories, electric actuators will play an even bigger role in fabrication. Integrated sensors will provide real-time feedback, enabling predictive maintenance and improved process control. IoT-enabled actuators can be remotely monitored, ensuring zero downtime and maximum efficiency.

As industries move towards sustainability, electric actuators will replace hydraulic and pneumatic systems, making fabrication greener, safer, and more productive.

Conclusion

The fabrication industry is no longer just about cutting and welding—it’s about precision, automation, and efficiency. Electric actuators have emerged as a game-changer, powering every stage of fabrication from raw material handling to finishing. By adopting actuator-driven automation, fabrication workshops can achieve higher productivity, reduced costs, and superior product quality.